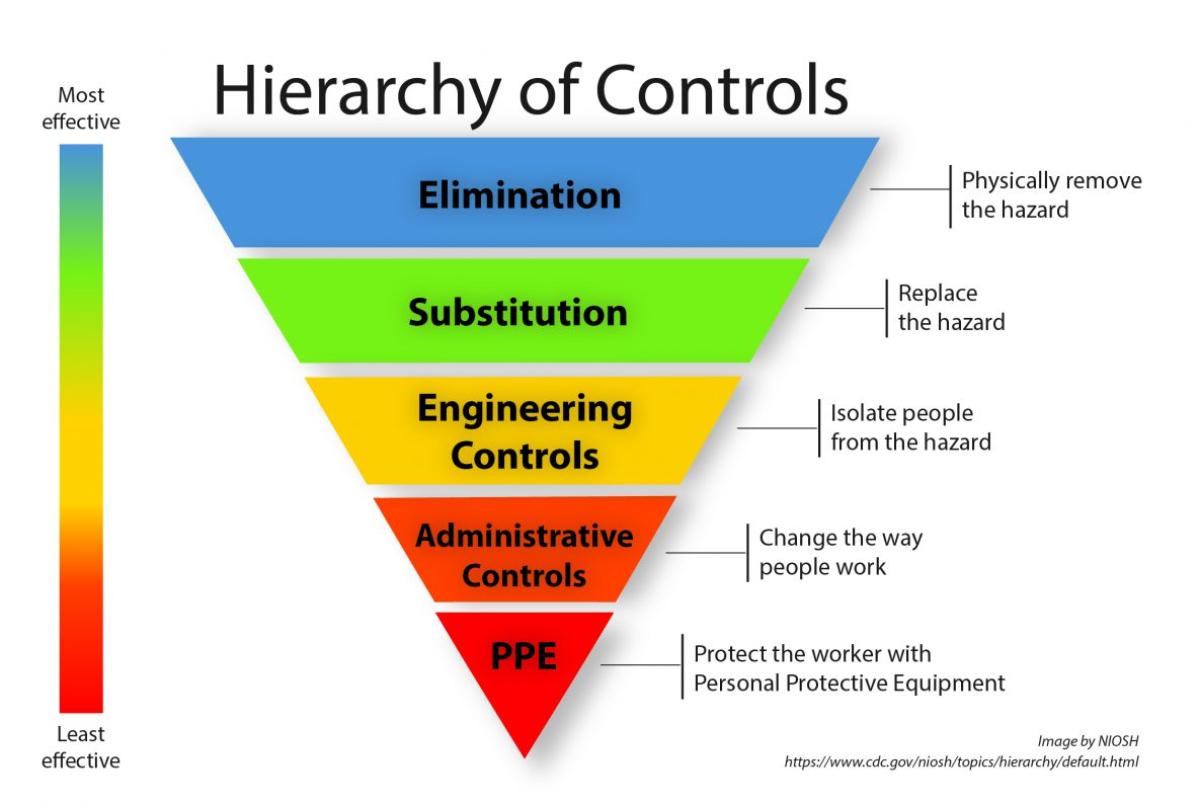

Eliminate Hazard | Remove the source of the MSD hazard to eliminate exposure. | - Effective and no further action is required

- Most practical and cost effective in the design phase

| | - Powered roller conveyor instead of carrying boxes

|

Substitute Hazard | Replace with another approach that reduces the risk of MSD. | - Can be almost as effective as elimination

| - Substitution may still have risks of MSD

| - Re-balancing similar work tasks throughout a production line to reduce cumulative exposure to MSD hazards

|

Engineering Controls | Modify the design of the physical workplace to remove or block the MSD hazard from the worker by machinery, tools or equipment. | - Effective long-term controls

- Used by all workers

- If installed and maintained, sustainable control of exposure to hazards

| - May appear expensive compared to administrative controls

| - Implementing lift assist devices, powered hand tools, etc.

- Removing obstructions or adding adjustability features

|

| Administrative Controls | Changes to the work organization and work practices to reduce exposure to MSD hazards, such as job rotation, pace of work, training, breaks, etc. | - A wide range of controls are available

- May not require physical changes to the workplace

| - Worker is still exposed to the hazard at some level

- Resources required for monitoring adherence

- Training and retraining

| - Job rotation schedules can reduce exposure time to MSD hazards

|

| Personal Protective Equipment (PPE) | Barriers between the worker and the hazard that are worn by the worker | - Considered cost effective

- Requires little change to the workplace or work organization

| - Ongoing costs for new PPE

- Resources required for adherence to wearing PPE

- Many types of PPE not shown to be effective for MSD even under good conditions

| - Only some anti-vibration gloves and knee pads shown to be effective

- "Back belts” not shown to be effective as a general workplace control

|