On this page

- Why take action to Prevent Musculoskeletal Disorders?

- Hazard Identification and Elimination, Risk Assessment and Control

Introduction

The MSD Prevention Guideline describes activities for primary prevention (before an injury occurs). It is a Guideline for changing the work to help prevent MSD. The Guideline offers guidance on workplace physical space, on the organization of work, and on organizational policies, practices, and procedures that can help prevent MSD injuries. The Guideline has a focus on changing the workplace, not a worker focus.

To help workers suffering from MSD to return to work more safely, a workplace focus is needed to reduce workplace hazards as well as focusing on the individual worker.

The core message from ergonomics is “Fit the work to the worker, not make the worker fit the work”. If the work does not fit the worker, pain, fatigue, injuries, errors and poorer quality of products or services result.

Humans are wonderfully adaptable and can often continue to work in tasks that do not “fit” humans, BUT the adaptation has a cost and that cost to the worker may be the development of MSD.

Why take action to Prevent Musculoskeletal Disorders?

It’s the law

In Ontario, there are specific regulations (e.g., Healthcare or Industrial Regulations) covering MSD hazards and resulting disorders, such as low back pain or shoulder injuries. MSD hazards are also covered by the “General Duty Clause” (In Ontario, Part III of the OHS Act, 25 (2)(h)). It remains the employer’s responsibility to identify and control MSD hazards.

It’s the right thing to do

Develop a plan to address hazards and issues reported by workers to prevent future pain and disability.

It's good for business

An MSD prevention program reduces direct and indirect costs of injury. Further, it improves product and process quality. There is a large amount of research linking the use of ergonomics in the design of production systems with improved quality performance in manufacturing. Factors for decreased quality identified in the analysis included those related to Product Design, Production Process Design, and Workstation Design while a much smaller number of factors are associated with individual factors.

Hazard Identification and Elimination, Risk Assessment and Control

There are specific approaches to identifying (recognizing) and eliminating MSD hazards, as well as assessing and reducing the risks associated with those MSD hazards.

If a hazard cannot be eliminated and the risk of developing an MSD reduced to zero, the hazard must be controlled, which reduces the risk associated with exposure to that [controlled] hazard.

Training on these specific topics by competent instructors should be done.

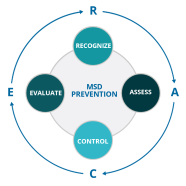

The general process for MSD Prevention is similar to other workplace hazards. This procedure is RACE:

- Recognize or identify an MSD hazard

- Assess its risk to workers or better still, eliminate the hazard

- Put in place Controls to reduce the risk to workers

- Evaluate the effectiveness of the control

Once the root (or underlying) causes of the MSD hazards have been determined, “controls” or workplace changes to eliminate them or reduce their effect are put in place.

Controls are divided into four main types, but often they are used in combination.

- Eliminate the hazard completely. This is your best option.

- Substitute a different method of doing the work.

- Change the workplace. Also called Engineering controls.

- Change how the work is organized. Also called Administrative controls.

- Personal Protective Equipment (PPE). Please note that anti-vibration gloves and knee pads are the only equipment that when matched to the specific situation can be effective in reducing the risk of developing MSD.

Recognize, Assess, Control, Evaluate (RACE)

The RACE process is referenced in each version of the Guideline.

Want to search the resource library?

Find all the available resources on the MSD prevention website, including posters, videos, and links to relevant websites.