On this page

- Repetition

- Static and Dynamic

- Duration of Work

- Duty Cycle

- Hand Activity Level

- Breaks, Pauses, Micro Pauses

- Rest Allowance

Introduction

Work is not a still picture - postures change, loads are lifted and tools are grasped. How postures and forces change over time makes a big difference to the musculoskeletal health and productivity of workers.

The term “repetition” is often used to describe this changing picture. Is it a high repetition or a low repetition job? Or does the person spend a long time bent over (a static posture), or are they frequently bending over then standing up (repetitive work)? Closely related concepts include recovery (does the body have sufficient rest time) and duty cycle (the percentage of time that the body is working or exerting force) .

Different studies and tools use different concepts to describe these time-related aspects of MSD hazards. Each way of describing them has merit. More recent studies and tools use concepts of duty cycle and recovery more frequently.

Repetition, duty cycle and recovery are highly dependent on Work Organization. See below to learn about the importance of Work Organization and MSD.

Repetition

Repeating the same activity over and over again is repetition. For time-related descriptions of MSD hazards, the definition developed by Dr. Barbara Silverstein in her groundbreaking work in 1986 is commonly used.

A High Repetition task was defined as:

- having a cycle time of less than 30 seconds,

OR - having more than 50% of the cycle time performing the same kind of fundamental cycles (also described as more than 50% of the work shift).

Otherwise it was classified as a Low Repetition task.

Static and Dynamic

Postures or forces are often described as static or dynamic.

- A static posture or force does not change (it is constant). Sitting in a chair using a computer is an example of a static posture of the back and shoulders. Note that the hands may not have static postures or static forces during typing. When using a mouse however, static postures of the hand and fingers may be seen.

- A dynamic posture or dynamic force means that it changes frequently with time.

Duration of Work

The duration of work has an effect on the risk of developing MSD. A work shift may be 8 hours in length but it may be 2 hours or as long as 12 hours. Some assessment methods include its effects. The longer the exposure to hazards, the higher the likelihood of developing MSD.

Duty Cycle (DC)

Duty Cycle is the percentage of time that muscles are active compared to when they are resting (recovering):

DC = [Time that the that muscles are active (sec) x 100%]/Time of a complete cycle of activity (sec)

OR

DC = [Time that the that muscles are active (sec) x 100%]/[Time that the that muscles are active + Time that the muscles are recovering in seconds]

Descriptions of Repetition based on Duty Cycle

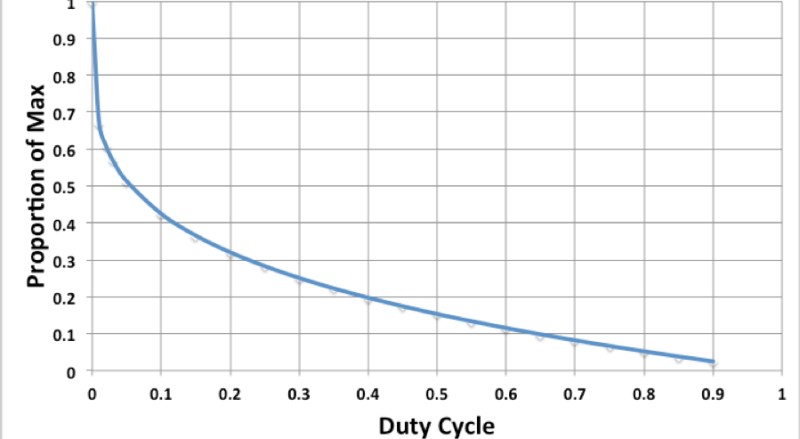

Prediction of acceptable efforts for repetitive tasks

Dr. Potvin synthesized data from multiple sources describing maximum allowable work based upon the psychophysical approach. The horizontal axis shows the duty cycle of the task. The vertical axis shows the proportion of a person’s maximum voluntary contraction that was exerted. The value of 1 corresponds to 100% of a maximum effort.

If the intersection of the two values is below the line, the task is acceptable but if the intersection is above the line, the task is not acceptable based upon this method. For example, a task with a Duty Cycle of 0.5 (50%) and a force of 0.3 (30% MVC) is above the line and is thus not acceptable. Note that efforts greater than about 65% MVC should be infrequent and very short to be acceptable.

ACGIH TLV for Upper Limb Localized Fatigue

The American Conference of Governmental Industrial Hygienists (ACGIH) published a Threshold Limit Value (TLV) for local fatigue. This method is similar to, and partially based upon, the relationships published by Potvin.

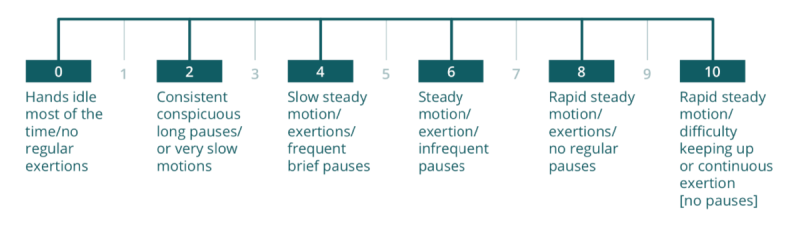

Hand Activity Level (HAL)

The HAL scale combines two aspects of time related MSD hazards: repetition and duty cycle. It was developed by Drs. Latko and Armstrong at the University of Michigan to better describe work using the hands. The HAL scale can be used to identify time-related MSD hazards. The HAL rating can also be used to help identify improvements to tasks.

The two ends of the HAL scale are:

- A HAL of zero (0) corresponds to a person’s hands being relaxed almost all of the time with very few hand efforts.

- A HAL of 10 corresponds to a person’s hand gripping or pinching almost all the time (almost no pauses) or their hands being in constant motion.

HAL can be estimated based upon observations by an individual or a group.

A video describing the HAL Scale can be seen here and a pdf can be seen here.

Next Steps with the HAL rating

Together with the grip force of the hand, the HAL rating can be used for risk assessment of the hand and forearm. The American Conference of Governmental Industrial Hygienists (ACGIH) published a Threshold Limit Value (TLV) for Hand Activity Level (HAL).

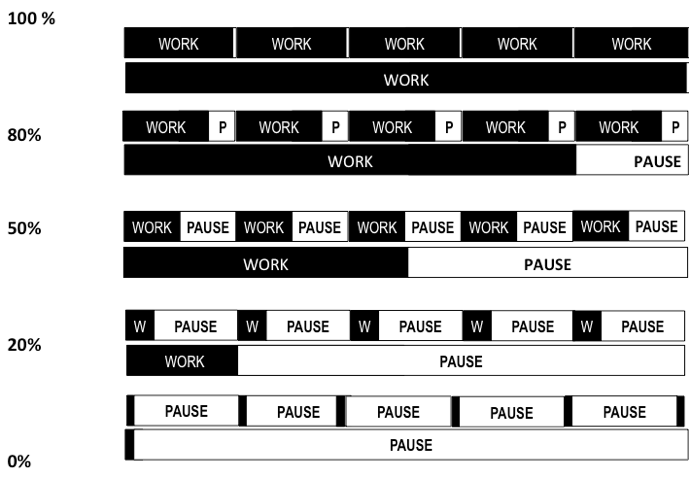

Breaks, Pauses, Micro-Pauses

The duration of time with no muscle activity or load - where there is a recovery possibility – can be described as Breaks, Pauses or Micro-pauses. For recovery, as the length of time with no activity decrease the number of them must increase.

Although there is no agreed definitions for these terms, the following table gives some examples.

| Duration | Example |

|---|---|---|

| Breaks | Often measured in minutes | A five minute tea break in the morning or afternoon. |

| Pauses | Often measured in seconds | A two second pause between parts on an assembly line when there is the possibility of recovery. |

| Micro-pauses | Often measured in parts of a second | Times during a task when there are very short periods when there is the possibility of recovery.

In a study of biscuit [cookie] packing, workers that developed neck and shoulder pain had a lower frequency of interruptions or “gaps” in sustained muscular activity and less muscle rest compared to workers without neck and shoulder pain. |

To be effective, a pause or micropause must allow for recovery. For this to happen the muscle cannot be contracting, it must be relaxed. For example, if a worker is drilling with a power tool and they must continue to hold the tool, even when no part is present, there would be no recovery. Suspending the drill on a tool balancer is a common workplace change that allows relaxation of muscles (and thus recovery) when no part is present.

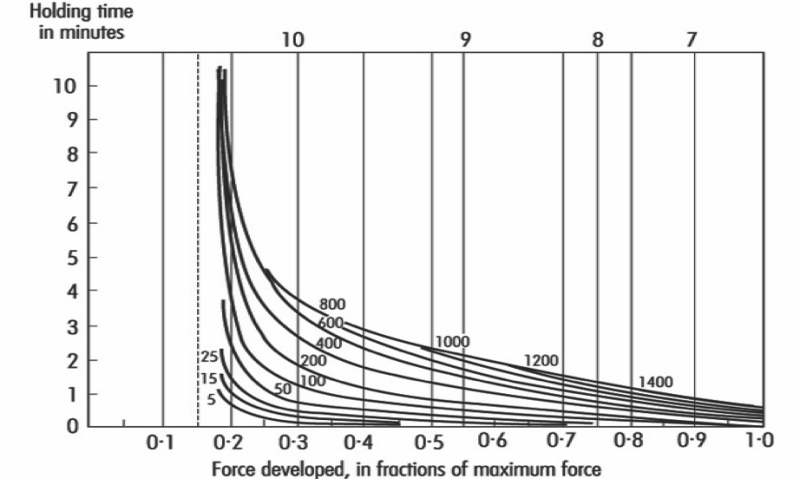

Rest Allowance

The rest allowance curves were published by Dr. Rohmert in 1973. The diagram shows the force exerted on the horizontal axis and the length of time that the effort is held (holding time in minutes) on the vertical axis. The contour lines show the recommended recovery time in percentage of the holding time for a given combination of holding time and force.

For example, for a force of 0.3 (30%MVC) and a holding time of 3 minutes, the intersection is approximately on the 400% contour line. The recovery time is therefore 12 minutes (3 mins x 400%). This would give a total cycle time of 15mins (3+12 mins), equivalent to a duty cycle of 20% (3/15 x 100%).

Note: Rest allowances are commonly used in industrial engineering time studies. These are not the same as the concept just described. A rest allowance as used in industrial engineering time studies is a factor applied to the job overall, for example 10%. It does not necessarily allow sufficient local recovery or protect a specific joint or body region from fatigue or the development of MSD.

Rohmert, W. (1973). Problems of determination of rest allowances Part 2: Determining rest allowances in different human tasks. Applied ergonomics, 4(3), 158-162.

Caution: The method predicts that efforts of 15% of a maximum Voluntary Contraction (MVC) or less could be held for ever. Later studies found this to be untrue. Caution must therefore be used when assessing tasks with efforts below about 25%MVC. The “Potvin” equation can be used in these circumstances.

Want to search the resource library?

Find all the available resources on the MSD prevention website, including posters, videos, and links to relevant websites.